WINTEC – Engel’s commitment to the middle market With a strong belief in high-quality products and reliable customer service, ENGEL has become the worlds leading supplier for injection moulding machines.

ENGEL stands for stability and consistency.

T-WIN – EFFICIENCY BY DESIGN

The servo-hydraulic two-platen t-win is the economic machine for your single-shot application. Applying decades of experience in injection molding the entire machine design is focused on fast and energy efficient production: from white goods to automotive or technical parts.

INVESTMENT IN PRODUCTIVITY & RELIABILITY

High output, consistent part quality and maximum machine availability are key to high productivity. With the t-win series we are looking ahead, offering an alternative to reduce Total Cost of Ownership. The combination of high productivity, energy efficiency, easy operation and maintenance ensure your return on investment. The extended service life – guaranteed by proven design, premium components and highest quality standards in production – makes your investment profitable for many years in the future.

HIGHER PRODUCTIVITY

Fast movements, short clamping force build-up time and synchronized locking device movement reduce total cycle time and increase productivity

HIGHER ENERGY EFFICIENCY

The servo drive system servowin guarantees fast acceleration and low energy consumption

INCREASED AVAILABILITY

The reliable and proven design as well as features allow fast access for maintenance and increase machine availability and output

PROFITABLE OPERATION

t-win generates value throughout decades and becomes profitable after a short period of time. The superior machine concept combines all elements of an economic production

SMALLER FOOTPRINT

The two-platen machine concept allows a compact design for less space requirements

LONGER SERVICE LIFE

Premium components and a design concepts that reduce wear on the machine – and on your mold – guarantee an extended service life of 15 to 20 years and more

PRECISE

Full-closed loop control design, accurate sensors and fast servo response ensure precise injection

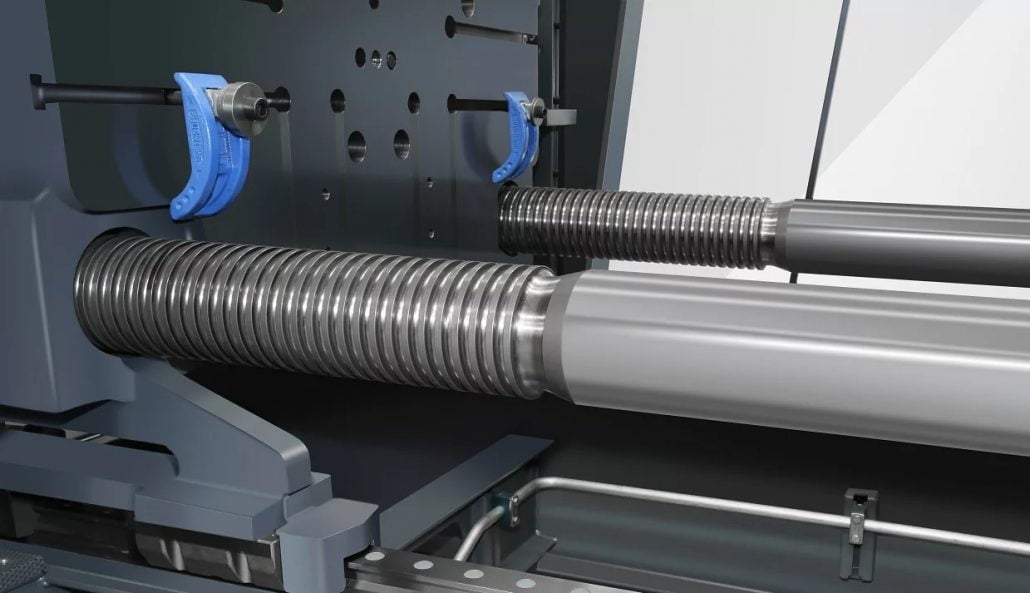

SPEED

Powerful servo drive components, ball screw and parallelism movement of every axis increases productivity

STABLE

High stiffness frame, platen, toggle system design and 900+ quality check points minimize downtime

SMART

Future oriented technologies with long-term availability and transformation. Powerful extending functions for future injection 4.0 challenges

ENERGY SAVING

Low friction linear guide, ball screw, tie bar free design and high efficiency servo drive guarantee low energy consumption

CONTROL UNIT C3

The C3 is the intuitive control for state-of-the-art machine operation. With future oriented technologies, long-term availability and innovative control the controller keeps you on top of processes that continue to become more and more complex. An extremely simple operation with the e-move make this control unit the perfect interface between you and your machine. The robots, which are fully integrated into the control system, and the uniform appearance set new standards in operation.

INTERESTED?

If you are interested in t-win please leave a message and we will get back to you.